Equipment which allows the movement of materials from one place to another is known as the conveyor system. This system is normally used to move those goods which are heavy in weight. These are pretty handy when it comes to the packaging and moving a bulk amount of goods in a short time in different industries.

They are also used in some of the well-known supermarkets and in airports for the handling of luggage. Each industry has a different kind of need and there are different kinds of conveyor systems available to satisfy those needs. Thus before we read about the different kinds of conveyor systems available.

Table of Contents

Here are a few benefits of using one:

1. This is a perfect system which saves your cost by replacing the expensive laborers. It can also be used as a safe means to transport multiple items at one go.

2. This system is able to save your time and work pressure in the industry.

3. They can be used anywhere and hence is a better option to lift the heavy items easily and safely.

4. This system works in different size and shape. Just the right selection of the system allows the user to use it for his purpose.

5. There are different types of options available which facilitate the user to choose the right one for locomotion like mechanical or fully automated.

Different types of conveyor system

There are different kinds of conveyor systems available depending upon the requirements of the user. Thus these are some of the popular systems which are used by various industries for different purposes in the modern days:

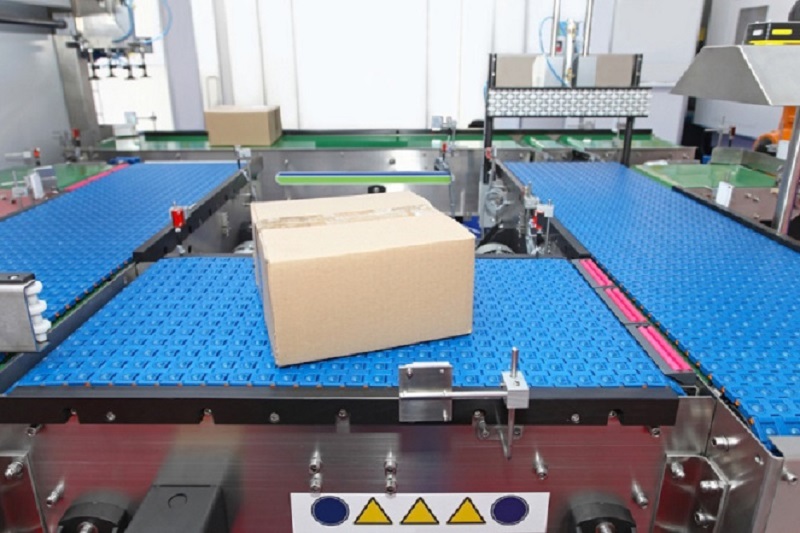

Plastic Belt Conveyors

These are the most effective ones when bulky items are transported. They can easily transport loose and packaged products from one place to another. This belt of the machine promises safe and effective transportation of items and thus delicate items are also transported through this system.

Pneumatic Conveyor Systems

Pipes and ducts which are known as transportation lines in this conveyor system are used to transport a group of materials at a time. The materials used should be in a free state such as cement and fly ash. The movement occurs due to air pressure created in the ducts and pipes.

These systems are available in two different categories; one is the carrier system and the other is dilute phase systems. Carrier systems only push items from the entry point to the exit point.

The other type; dilute phase system. This is used in the technology of pull and push pressure system to send items from the various entry points to the different exit points.

Sanitary Conveyor

As the name suggests, this type of conveyor belt is used to transport items which need extreme hygiene. Stainless steel components are the basic components of this system. The entire system goes through a wipe down and extreme pressure wash downs frequently. Industrial cleaning agents are used to maintaining the hygienic conditions of the conveyor system.

Vibrating Conveyor Systems

This machine is used in food industries to shift bulk solid food items at a time. The items go through solid sanitation or cleaning and washdown which is mandatory according to the food industries norms. The system functions perfectly in an extremely rough, hot and dry climate as well. Sorting, screening and orienting are certain functions performed by these conveyor systems.

Flexible Conveyor Systems

The conveyor beams based on aluminum and steel are known as flexible conveyor systems. Products which are transferred through this system are directly placed on the belt or on the plastic trays which are kept on the belt. This system is easy to use even when certain obstacles are kept in the middle. This particular system is used in food packaging and pharmaceutical companies.

Hence these are some of the most popular conveyor systems available in different kinds of industries. You need to choose the best conveyor systems according to your purpose to get the best result from the modern conveyor system.

Alex is fascinated with “understanding” people. It’s actually what drives everything he does. He believes in a thoughtful exploration of how you shape your thoughts, experience of the world.